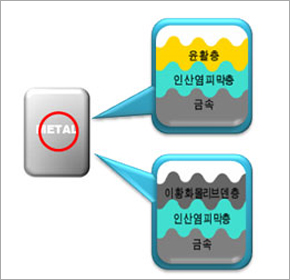

Coating / Lubricant

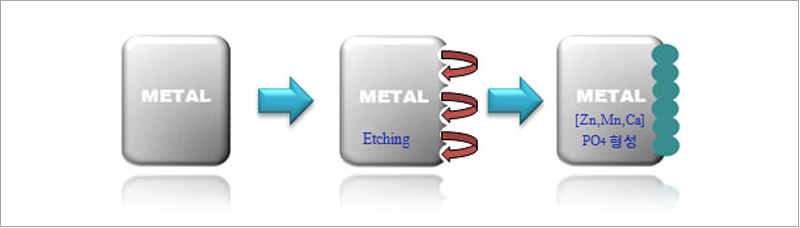

Metalsurface Treatment Process

The phosphate coating process takes place in a way that phosphate crystallization of formless coating is created on

the non-metal substances and the non-conductive metals through chemical reaction process. It is otherwise called

parkerizing or bonderizing. As the phosphate coating treatment is simple and incurs low production costs, it is consid-

ered as an economical chemical coating treatment for the pretreatment of steel. The phosphate coating is used for the

basic work for the painting as well as for the metal cold forging for plasticity processing. It has been also widely used

for the pretreatment purposes, such as abrasion-reistance, electric insulation, corrosion-resistance.

The main purpose of the Iubrication treatment

The main purpose of the lubrication treatment is not

only to resuce the friction between the tool and the material,

but, also to prevent adhesion that could take place due

to the direct contant between the metals of the tool and material

Highly lubricant and heat-resistant MoS₂

This is contained in molybdenum that can be excavated from the

nature, while providing the most excellent friction-resistance and

abrasion-resistance properties As it is also highly superior in terms

of heat-resistance, adhesion and cohesion, it provides

excellent effect of plasicity processing.